Entries submitted to several student inhaler and medical device design contests over the past year envision some radical changes in inhaler design. These concepts, created by students who range in age from primary school through college, provide some insight into the students’ priorities when it comes to inhalation devices — all of the inhalers they created emphasize functionality and/or appearance over the ability to fit the device easily into a pocket, for example. For the college-age students, their participation in the competitions also offered a look at the complexity of the inhaler design process and the expense involved.

Poster describing the LIYEN inhaler

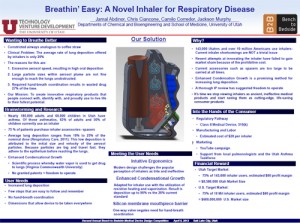

Given the complexity and expense, it’s unsurprising that none of the student designers managed to develop a working prototype during the course of the competitions, but University of Utah and Westminster College students Jamal Abdinor, Camilo Corredor, Jackson Murphy, and Chris Ciancone say that they intend to use their $20,000 winnings in the University of Utah’s Bench to Bedside Medical Device Competition to complete development of their pMDI and bring it to market.

The prize money includes $5,000 they took home for having the best business plan in the competition, and the four now plan to form a company to commercialize the LIYEN (“Last Inhaler You’ll Ever Need”) device, which makes use of Virginia Commonwealth University research on enhanced condensation growth. The designers say that the LIYEN inhaler requires no hand-breath coordination and could result in up to 90% deposition.

The team decided to “reinvent the inhaler” after Ciancone, an asthmatic who was unhappy with the “poor design and inefficiencies” of the inhalers available to him, pitched the idea to the others. Their first challenge was getting access to textbooks like Drug Delivery to the Lung and to journals like the Journal of Aerosol Medicine, the Journal of Aerosol Science, Pharmaceutical Research, Inhalation Toxicology, and Computer Methods in Biomechanics and Biomedical Engineering without having to spend thousands of dollars they didn’t have.

Prototype of the LIYEN inhaler

After getting a feel for the factors involved in inhaler design from these sources, they consulted the FDA guidance, conducted focus groups with asthmatics, and enlisted the help of a patent expert at the university to determine the intellectual property landscape. Although they intended to make a working prototype, they had to settle for a non-working model due to budget concerns.

Even if they had managed to create a working inhaler from their design, they say, they would have been unable to run tests. “We looked into renting a cascade impactor from an out-of-state supplier in the event we’d have a ready-to-test prototype,” they recall, “but the rent for the month was approximately our entire budget for the competition.”

Instead, the team sought help from a chemical engineering faculty member who helped them to run CFD simulations to validate their design.